Flow Injection techniques would not pass the ultimate test set by Elo Hansen, since it may be argued that reagent based assays can be automated by either air segmented (AutoAnalyzer®) or by discrete parallel batch analyzers, but he is right in that that the goal should be to develop a unique tool. And his opinion stands in contrast to the litmus test used in Academia and scientific publishing, where it is accepled that all what is needed is a degree of novelty, to make an analytical method valuable.

Since, in my opinion, the role of analytical chemistry is to provide solution to real life problems, the test of analytical method should be that it is better suited for a given task than what has been available so far. And this brings us to definition of “better” which may have many aspects: precision, accuracy, sensitivity, selectivity, speed, reliability, versatility, mobility, cost etc…

So what are the virtues of microSI that make it “better” than other approaches? They are:

- Speed of response – for fast chemical reactions the readout is available within 30 seconds after sample injection

- Low reagent and sample consumption –in the order of tens of microliters and possibly down scalable

- Versatility – suitable for a wide range of reagent based assays

- Automation of single step separation integrated with quantification of an analyte

- Stand by operation- the instrument can be idle and assay performed “on demand” at required intervals

- Robustness, small footprint and portability.

- Single standard calibration

- Ability to monitor and exploit kinetics of chemical reactions

Next in Applications?

2.2.42.E.

The ultimate test for an analytical approach is not that it can do better what can be done by other means, but that it permits us to do something that we cannot do in any other way.

Elo H. Hansen

Therefore the applications that will benefit from miniSIA platform are:

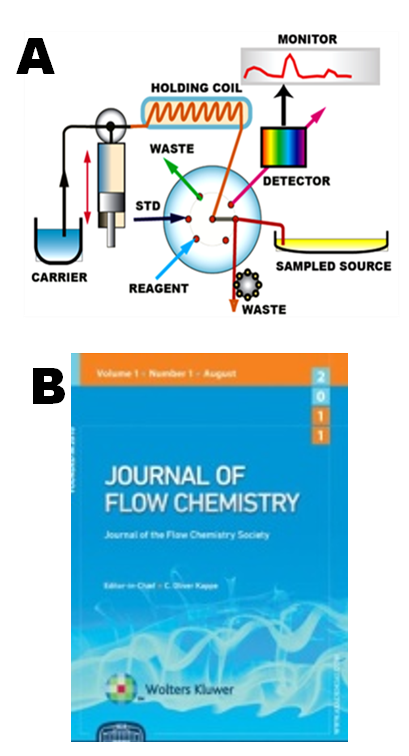

Continuous monitoring, because the short response time of miniSIA allows immediate repetition of the monitored event, should it be required, or should its result be in doubt. Also single standard calibration is an important feature, should the instrument be deployed in the field (A). Readout–on–demand capability is an attribute, essential for monitoring of any system, whether it is an industrial process, or a research project in oceanography or in biotechnology. Thus if, if, e.g. a fermentation tank needs to be monitored for ammonia content in 15 minutes intervals over period of 24 hours, miniSIA instrument can be programmed accordingly, delivering a readout when required, while standing by idle ( not using reagents or power when sample is not being analyzed).

High sensitivity assays in a laboratory or on board for chemical oceanography, where low reagent consumption and waste generation is a must. Also robustness, reliability and small footprint miniSIA instrument may one day lead to its use on deployable systems.

Serial assays of nutrients (phosphate, ammonia, nitrate, nitrite) using less reagents and consumables, such as peristaltic pump tubing.

Study of (bio) chemical reactions and micro synthesis. The recently established Journal of Flow Chemistry (B) highlights the novel approach to (organic) synthesis performed within microfluidic systems that resemble flow analysis instrumentation, except that flow trough detectors are only seldom used for monitoring of resulting products and flow programming is not being used. Considering that reagent based assays can be used as synthetic chemistry, it does not require a leap of imagination to conclude that microSI methodology may find application in Flow Chemistry .